Why We Cannot Use a CNC Router Instead of a Thick Wood Cutting CNC Machine?

In the realm of carpentry, the decision of apparatus essentially influences the quality, productivity, and plausibility of tasks. Among the different sorts of CNC machines accessible, CNC switches and thick wood-cutting CNC machines fill particular needs and are intended for explicit applications. While the two sorts of machines are vital to current carpentry, they are not compatible.

While CNC switches and thick wood cutting CNC machines are both fundamental apparatuses in the carpentry business, they are not compatible. The primary distinctions, cutting capacities, accuracy, material dealing with, sturdiness, and application particularity all feature why a CNC switch can’t fill in for a thick wood cutting CNC machine. A thick wood cutting CNC machine guarantees the accuracy, proficiency, and dependability expected to create excellent items, eventually prompting better progress and manageability in the carpentry business.

Difference between cnc router and a thick wood cutting cnc machine

Underlying Contrasts

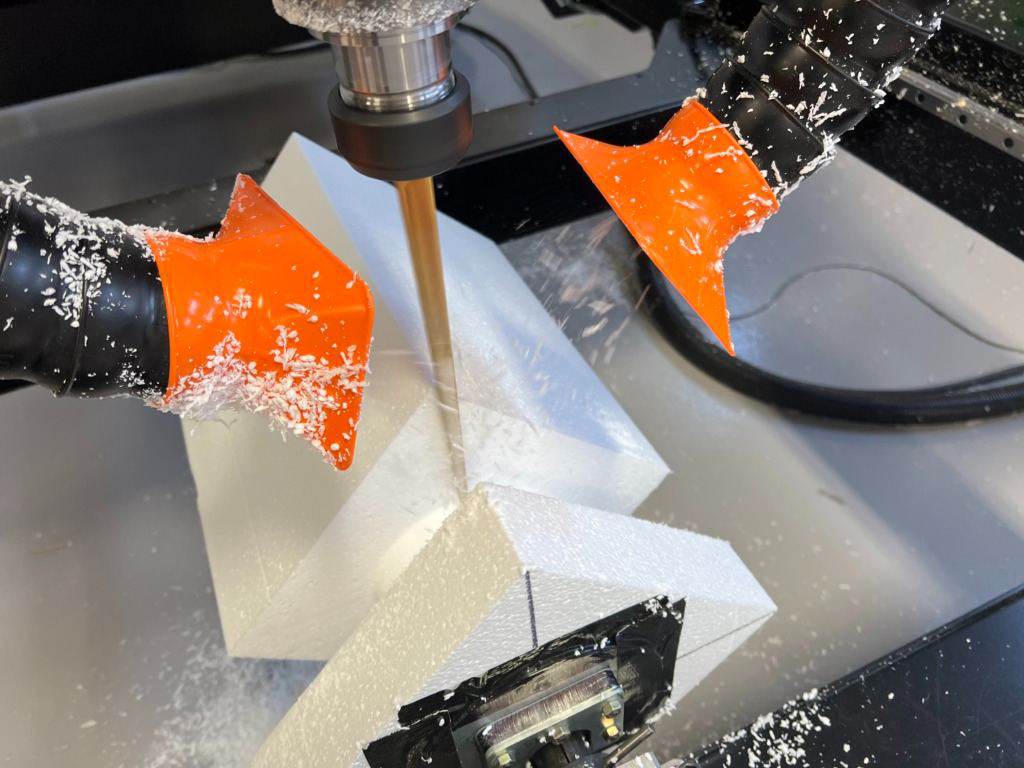

The underlying model of CNC switches and thick wood cutting CNC machines is essentially unique, mirroring their expected purposes. CNC switches are by and large intended for lighter work, frequently including materials like plastic, froth, delicate metals, and slight wood. They are worked with a gantry structure that offers satisfactory help for these materials however isn’t sufficiently powerful to deal with the burdens of cutting thick, thick wood.

Then again, a thick wood cutting cnc machine is designed with a lot sturdier and heavier development. They frequently highlight a supported edge and an all the more remarkable shaft engine, equipped for taking care of the significant powers engaged with slicing through thick hardwoods. This upgraded primary trustworthiness guarantees steadiness and accuracy, considerably under weighty burdens, which is fundamental for keeping up with exactness and delaying the machine’s life expectancy.

Accuracy and Exactness

Accuracy is vital in carpentry, particularly while working with thick wood, where even minor deviations can prompt critical issues in the result. CNC switches, while exact for lighter undertakings, frequently come up short on unbending nature and steadiness expected for keeping up with precision while slicing through thick materials. The flexing and vibration that can happen when a CNC switch is pushed past its plan limits bring about errors and low-quality cuts.

Thick wood-slicing CNC machines are intended to limit these issues. Their vigorous development and strong shafts guarantee that they can slice through thick wood without huge flexing or vibration. This soundness is urgent for keeping up with the tight resiliences expected in excellent carpentry projects. Whether cutting huge boards or unpredictable joinery, a thick wood cutting CNC machine conveys the accuracy expected to guarantee a perfect completion.

The demands of a thick wood cutting cnc machine

Taking care of thick and weighty wood requires a machine that can uphold and control these materials without settling for less security or exactness. CNC switches are for the most part not intended to deal with the weight and heft of enormous, thick wood pieces. Their worktables and gantry frameworks may not offer the essential help, prompting potential well-being risks and mistaken cuts.

Thick wood cutting CNC machines are outfitted with highlights intended for taking care of significant materials. Their worktables are frequently bigger and more powerful, fit for supporting weighty wood pieces safely. Furthermore, these machines now and again consolidate progressed clasping frameworks to hold the material immovably set up during cutting, guaranteeing both well-being and accuracy.

Sturdiness and Upkeep

The requests put on a machine cutting thick wood are fundamentally higher than those cutting lighter materials. CNC switches, when utilized past their expected limit, can encounter quick mileage, prompting incessant breakdowns and expanded support costs. Parts like shafts, orientation, and removing devices wear a lot quicker when exposed to the burdens of cutting thick wood.

Thick wood-slicing CNC machines are worked to endure these requests. They utilize hard core parts intended for a life span under demanding circumstances. The expanded solidness of these machines implies less personal time and lower upkeep costs, which means higher efficiency and cost reserve funds over the long haul.

The limitations of cnc routers

Each sort of CNC machine is planned in light of explicit applications. CNC switches succeed in errands like sign making, etching, and cutting slender sheets of material. Their flexibility in taking care of a large number of materials makes them ideal for light-obligation undertakings however unsatisfactory for the afflictions of thick wood cutting.

Thick wood cutting CNC machines are particular apparatuses planned for explicit errands that include slicing through thick and thick wood. They are vital in ventures, for example, furniture making, cabinetry, and enormous scope wood development, where accuracy and dependability in cutting thick materials are essential. Endeavoring to involve a CNC switch for these applications compromises the nature of the work as well as overburdens the machine, prompting shortcomings and likely disappointments.